The foundation for smart production

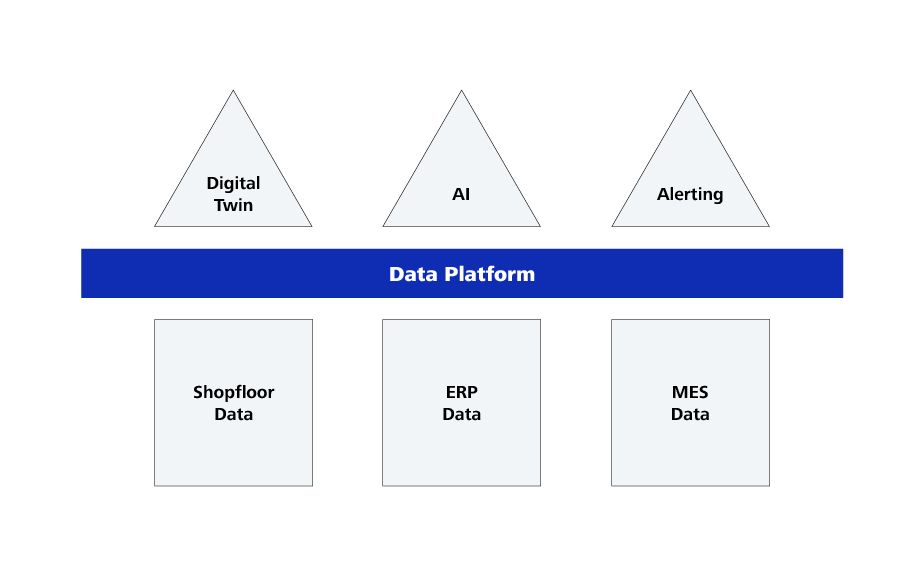

All modern digital technologies designed to optimise production, such as digital twins and artificial intelligence; or traditional methods, such as process-data monitoring and alerting, have one thing in common: they can only be implemented if high-quality process data is provided. If this is not the case, modern digital technologies cannot be deployed.

This means that before a company can start using AI, for example, it is vital to look at what data is provided and where it comes from. To prevent a company from having to start from scratch whenever any new applications are required in the future, it is advisable to choose a general, generic approach for collecting and providing data. This involves a type of middleware that we will refer to in this post as a “data platform”.

The primary role of a data platform is to gather and combine data from lots of different data silos. In a factory that operates discretely, this data is primarily machine data (for example, process data over time, alerts, status messages), order data from the ERP system (for example, job orders, work processes, parts lists, batch numbers, part and assembly numbers), MES data (for example, storage locations, interim storage times, machine utilisation rates) and a range of data from third-party systems depending on the industry model, for example from CAD and CAQ systems. This data is always present in modern production environments, but it cannot be correlated or rendered capable of being analysed without a data platform.

Just like any software, a data platform can be implemented in two ways: as standard software or as customised software, tailored to meet the needs of a specific customer. In the next section, we will consider the pros and cons of the various possible solutions.

Data platform as a standard product

For a number of months now, more and more manufacturers have been marketing a range of standard products. Some of these products have universal applications; others are tailored very specifically to cater towards a particular sector. The advantage of standardised software is obvious: in an ideal scenario, it can be available and ready to use very quickly. Moreover, in most cases it also includes business applications that can be used to solve current problems and issues. In some cases, even people who are not IT experts will be able to operate the business applications, without requiring a data engineer.

But does this out-of-the-box thinking really add value when it comes to the digital transformation of a factory? The fundamental problem with digital transformation is that it requires employees to change their way of thinking with regard to data-driven production. Given that most employees have not encountered this type of software before, they are often unable to say what they need or want from a data platform. It is difficult or even impossible to make an objective, systematic comparison between multiple products from different manufacturers. This is why a company may pay high capital costs and licence fees for a sub-standard product, or take a very long time to realise that the product is not suitable for its needs. Small- and medium-sized software producers only offer a certain level of investment security because they also need to respond dynamically to the market. In some cases, this may mean that support for a particular product disappears overnight.

Customised cloud-native solution

To meet the ever-changing requirements that the process of digitally transforming a company presents, it may be preferable to choose a customised software solution for the data platform. In recent years, the cloud-native services provided by the big hyperscalers Microsoft Azure and Amazon Web Services (AWS) have emerged as the technology of choice. They offer one crucial advantage: choosing modern technology services that are available in the form of Platform as a Service (PaaS) means that the potential data platform solution will be high-performing, cost-effective and sustainable in terms of the longevity of the software code. This results in a very high level of investment security. The data platform is always programmed by an integrator such as ZEISS Digital Innovation using the services of a hyperscaler. This combination also delivers further benefits. Unlike a standard product from a specific manufacturer, the customer can also operate the customised solution themselves once it has been completed. If necessary, it can even be operated by third parties. This reduces reliance on integrators, which is hugely beneficial if the data platform is intended to operate for ten to twenty years or more. Reliance on hyperscalers is a more minor issue. When the integrator is choosing the PaaS technologies, it can utilise technologies that are available from more than one hyperscaler. Although switching from Microsoft to AWS or vice versa involves a little work, it is definitely possible. This step enables the customer to take action if a hyperscaler increases its operating costs in the future.

Accessibility facilitates co-innovations

The findings that have been discovered as companies have started their digital transformation as part of the fourth industrial revolution demonstrate a compelling need for co-innovation. This means close collaboration between several industrial partners that utilise their very specific expertise to create a level of combined added value for customers that is greater than the level individual companies would be capable of delivering on their own.

The customised cloud-native solution offers this very advantage of accessible collaboration between several companies on the data platform. In the context of the PaaS solutions from a hyperscaler, the specific business applications that represent an exact fit for the application you need to implement in your company can be purchased from or programmed by third-party companies. With this foundation in place, it is then possible to add state-of-the-art technologies like AI or digital twins at any time, making you a pioneer in your own industry and generating a real competitive advantage.