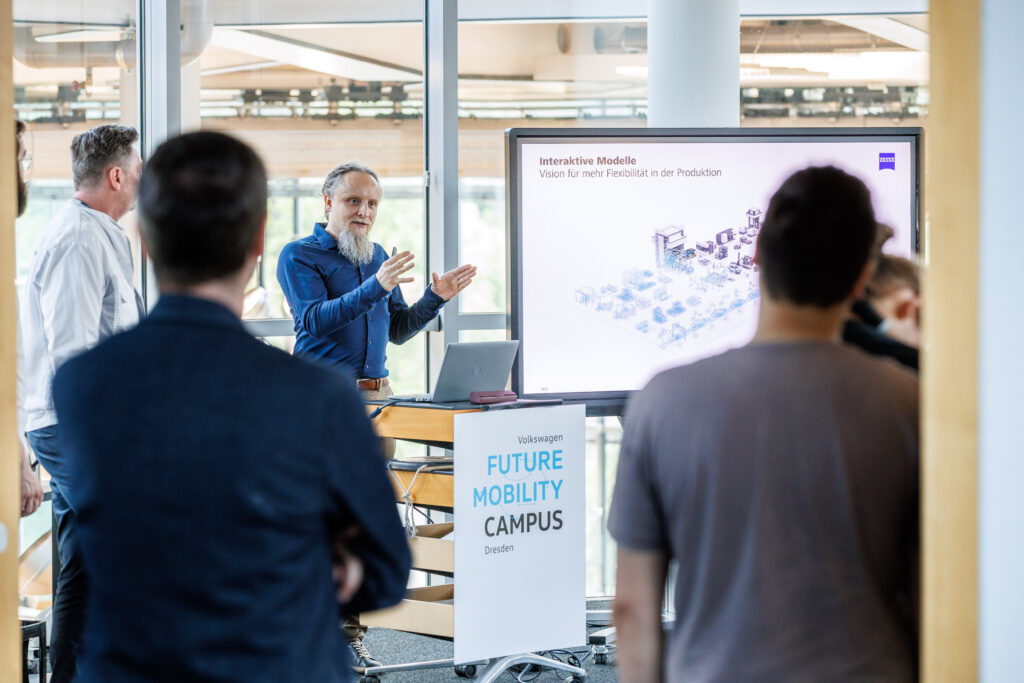

How do you bring a physical production hall into the digital world? This question was at the heart of the Thin[gk]athon, with ZEISS Digital Innovation and Volkswagen Sachsen as the challenge owners. The co-innovation format of the Smart Systems Hub provides the methodological framework to collaboratively tackle highly relevant challenges. This time, the motto was “Taking Virtual Shopfloor to the Next Level,” inviting ambitious minds with diverse professional backgrounds to jointly explore the boundaries of digitalization. The result: interdisciplinary teams where fresh perspectives met diverse experiences to develop innovative solutions.

The Challenge: Making Digitalization Tangible

At the center of the challenge was the task of transferring real production data into a virtual 3D world – interactively, scalable, and practically. The teams had to link scanned production environments, comprised of point clouds and images, with digital product passes. Specifically, this meant autonomously recognizing QR codes in the 3D scans and linking them with information from the Asset Administration Shell (AAS). The goal was a walkable, interactive 3D scene that not only visualizes the environment but also provides data and optimizes processes. To make the results transferable, a generic approach was chosen.

26.06.2025, Dresden, Thin[gk]athon, ZEISS Digital Innovation, Smart Systems Hub, Volkswagen Sachsen

Teamwork as an Innovation Driver

The teams, consisting of participants with diverse professional backgrounds, demonstrated how valuable this format is. By combining knowledge from IT, production, design, and science, new ideas emerged that replaced conventional thinking with fresh impulses. Our colleagues Pawel Adaszewski and Gergely Honti from ZEISS Digital Innovation also supported the teams with their expertise in software development and their shopfloor experience. In the end, all teams presented practical concepts within just three days and outlined possible next steps for building an interactive and scalable digital twin.

Technological Deep Dive: A Challenge in Three Dimensions

The true complexity of the challenge was revealed in the raw data. The datasets were in the form of so-called 3D Gaussian Splats – a modern method for rendering photorealistic scenes from photos. The result: a huge and often noisy point cloud that first had to be filtered from noise. Some teams tried to analyze the density of the point cloud with the K-Nearest-Neighbors algorithm (KNN) but quickly abandoned this approach due to the enormous amount of data. More successful was a box-based method that divided the space into a voxel grid – imagine this as a division into small cubes. By calculating the point density in each cube, machine clusters could be quickly and efficiently isolated.

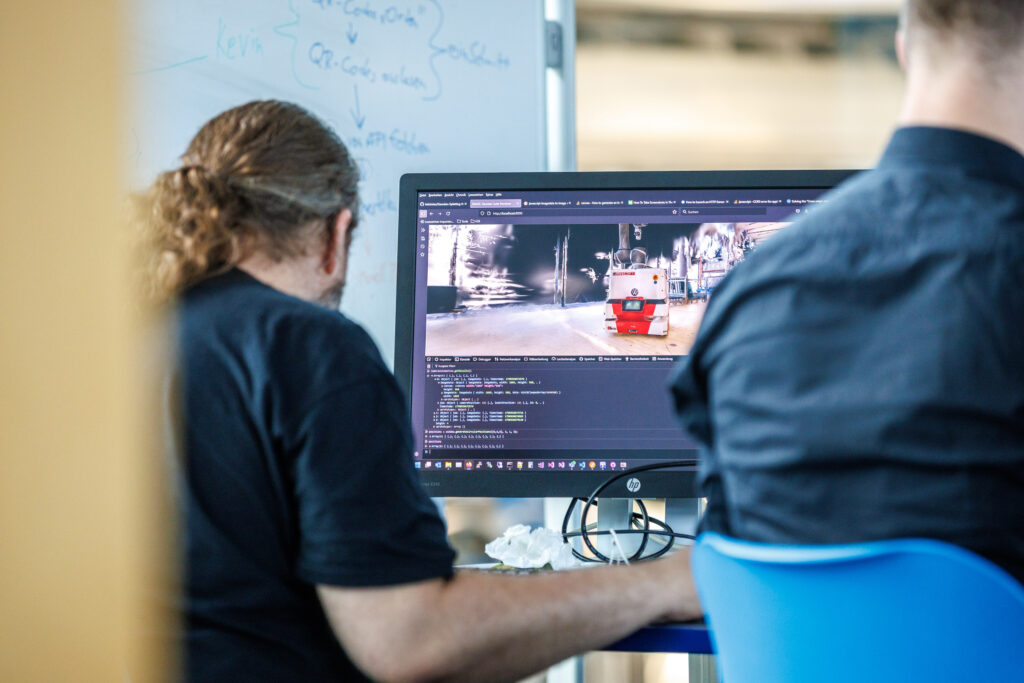

The biggest hurdle remained the detection of QR codes. The crucial insight was that the 3D scans only depicted the surfaces of the objects. Instead of searching the entire 3D space, the teams could specifically search the rendered surface for areas with high black-and-white contrast. However, the practical implementation was rocky: attempts to visualize the found contrast hotspots with Python-based 3D renderers failed due to software conflicts and bugs. The breakthrough finally came through a pragmatic switch to the Unity engine. Using WebGL rendering, the virtual camera was moved to the calculated coordinates to find and read the QR codes.

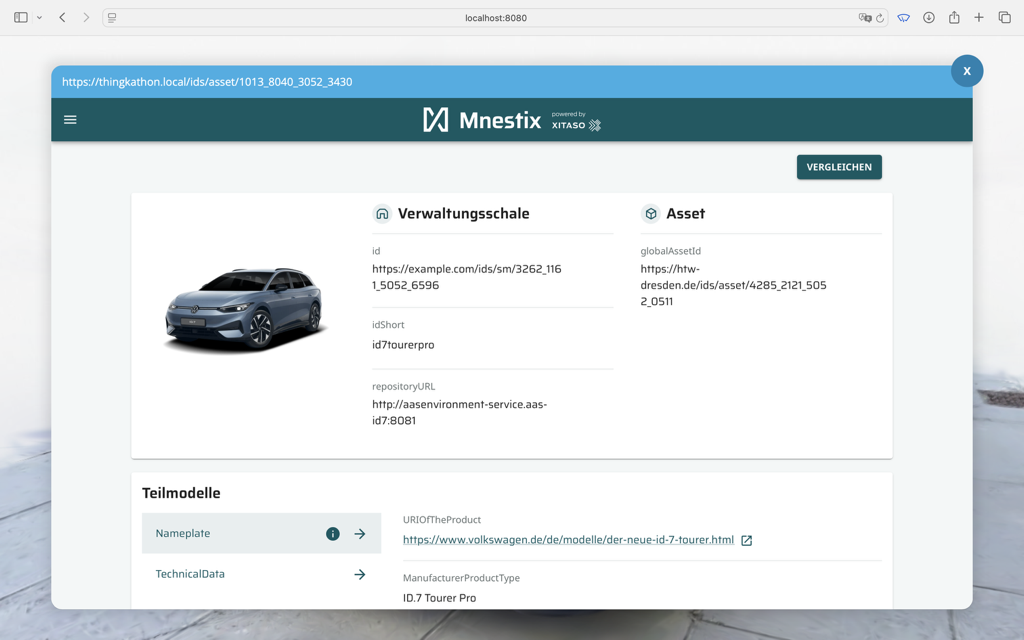

After preprocessing, a spatial relationship between the QR codes and the associated machines was established. This spatial relationship was used to retrieve data from the Asset Administration Shell (AAS) for the user and display it in an interactive user interface. A possible frontend allowed users to interactively navigate through the point cloud and explore the relevant information.

The Winning Team’s Solution

The winning team from the Information Management department at HTW Dresden – consisting of Stefan Vogt, Robert Pampuch, Johannes Metzler, Felix Fritzsche, and Paul Patolla – impressed with a functioning solution that also won the competition. For them, it was three intensive days full of technology, exchange, and practical development.

| “This event brings together the challenges of the economy and the knowledge from research and shows how convincing solutions can be developed together in a short time,” says Paul Patolla from HTW Dresden. |

The technical processing of their solution was based on several steps. First, video files were broken down into individual frames to identify QR codes along with position information in each frame. For this, they primarily used the Python library OpenCV, which enabled efficient image preparation and robust QR code recognition. In parallel, the team used the Gaussian Splatting method, based on the scientific publication by Kerbl et al., to generate a realistic point cloud from the image data. This allowed the precise localization of the QR codes in a three-dimensional context.

For visualization, Babylon.js was used, allowing the results to be experienced directly in the browser (and optionally in VR) as a WebXR application. Additionally, NVIDIA Omniverse was used to generate textures, significantly enhancing the visual quality of the representation. This way, a comprehensive solution was created that intelligently combined data analysis and immersive 3D visualization, demonstrating a clear connection to practice.

Conclusion and Outlook

A panel of experts from industry and academia evaluated the concepts based on technical depth, feasibility, and teamwork. The teams demonstrated a strong commitment to social responsibility by donating their prize money of €2,000 to charitable organizations.

Winning team “Punkt Pioniere”

The Thin[gk]athon once again proved that the digitalization of production is not an end in itself but an effective tool. It enables more efficient processes and data-based decisions that create sustainable added value for the shopfloor. The key to success lies in structured data enablement and the targeted use of existing production data.

The developed concepts impressively show how complex challenges can be solved through the combination of technology, team spirit, and methodological support. We look forward to continuing formats of this kind and further promoting exchange together.